pool resin, 100% PCR Material Made in Japan, Regularly Adopted for Packaging by Toyota Tsusho. Aiming for Carbon Neutrality and Utilization of Circular Plastic in Packaging for Automotive Parts with Incorporating PCR Materials.

Recotech Co., Ltd. (hereinafter “Recotech”), using Circularity Design Tool – pool (hereinafter “pool”), has commenced regular supply of pool resin, a domestically produced 100% PCR material with traceability ensured through collection and recycling, as their packaging material used in automotive parts by Toyota Tsusho Co., Ltd. (hereinafter “Toyota Tsusho”).

Background

In recent times, urgent global challenges such as the climate crisis and the ocean plastic pollution have made achieving decarbonization and a circular economy a pressing need globally. Concrete legislative measures, such as reducing plastic waste and mandating the use of recycled materials, have been actively pursued, especially in Europe and the U.S. For instance, in the UK the Plastic Packaging Tax was introduced in April 2022, imposing a tax of £200 per ton on plastic packaging with less than 30% PCR content that is manufactured or imported. Similarly, in Japan, the Plastic Resource Circulation Promotion Law (hereinafter “New Plastic Law”) was enacted in 2022, promoting legislative efforts to encourage plastic circulation across municipalities and businesses.

Especially in the automotive industry, regulations proposed by the European Commission in July 2023 mandate that 25% of the plastic used in manufacturing new automobiles must be made from recycled materials. Of which 25% must be recycled materials sourced from end-of-life vehicle parts.Therefore, urgent adoption of PCR materials has become a significant challenge with both the automobiles itself and the packaging for components.

In response, Toyota Tsusho has initiated the Circular Logistics (CL) project to achieve waste-free logistics, promoting low-carbon through the use of recycled and biomass materials in its logistics. Particularly, in the use of recycled materials, Toyota Tsusho prioritizes the use of PCR materials to minimize waste and circulate resources within its business. The company has begun gradually transitioning its group’s materials to low-carbon materials, aiming for full deployment in all logistics for automotive parts by 2024-2025 and targeting 100% Circular Logistics by 2030.

About pool resin

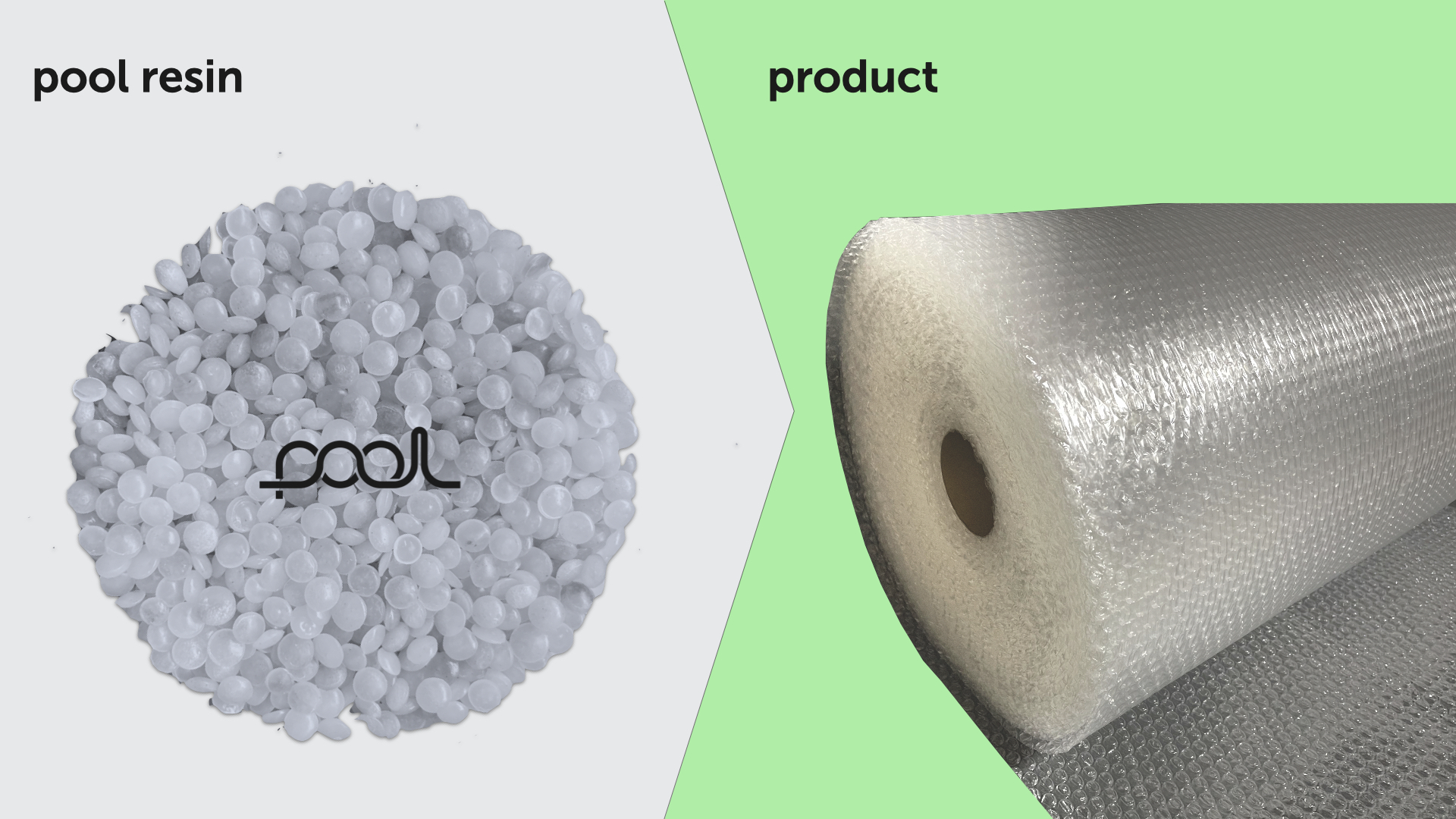

“pool resin” is a 100% PCR material that is produced in Japan, deriving from discharged plastics collected from commercial facilities. By carefully selecting raw materials and managing them via “pool”, Recotech is able to provide high-quality PCR materials with ensured traceability.

・High Quality

Mainly uses PP/PE with minimal contamination and dirt, focusing on hanger covers and protective bags discarded in the apparel industry.

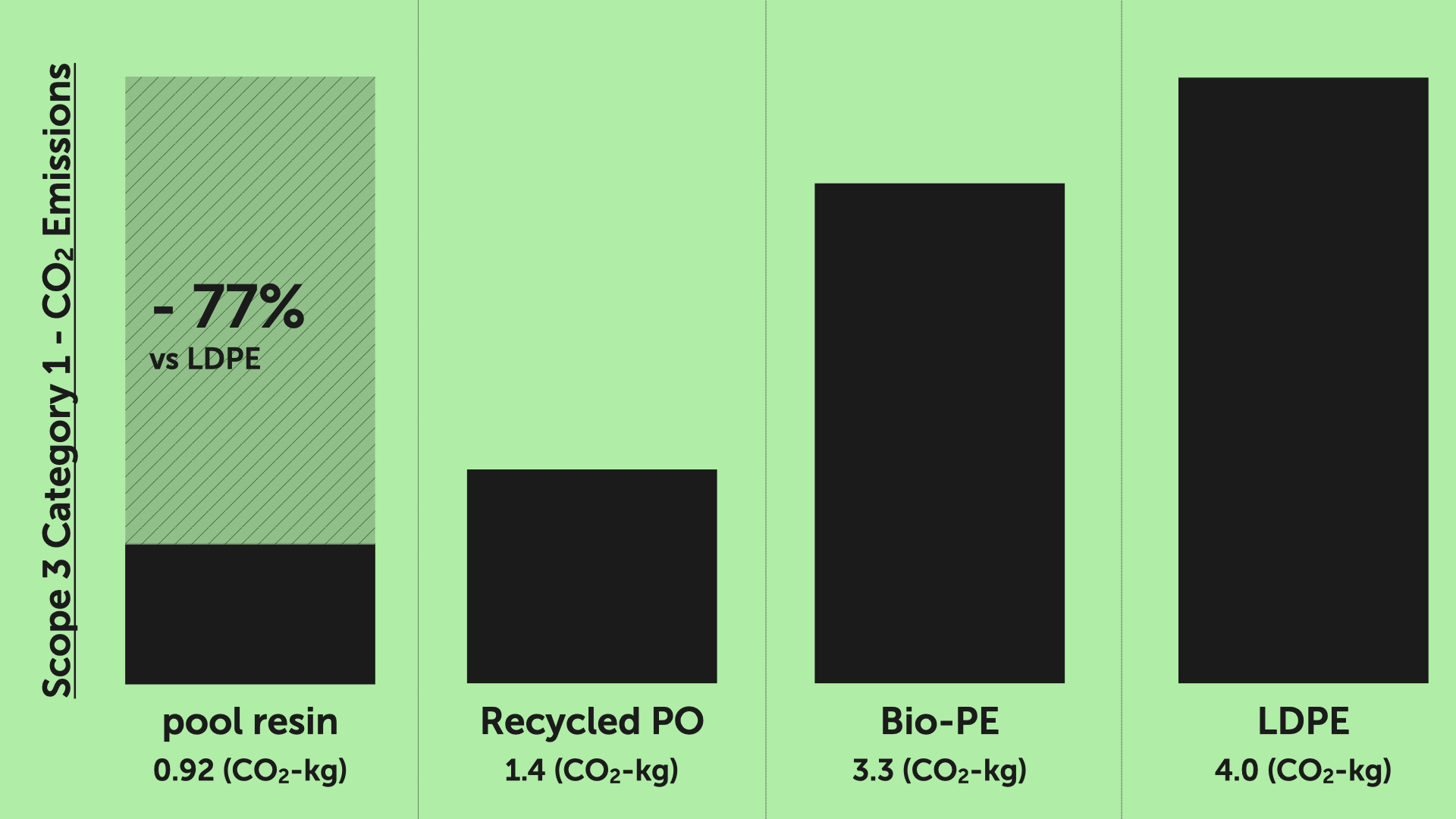

・Low Carbon

Precise sorting at the point of discharge eliminates the high-energy processes such as mechanical sorting, washing, and drying typically required in the recycling process of discharged plastics.

・Low Cost

By collecting discharged plastics on return routes of delivery vehicles, collection costs are reduced.

・Traceability

pool manages data throughout the process from the origin of materials to collection, storage, and recycling.

[Comparison of Scope 3 Category 1 Emissions]

[Product Implementation]

“pool resin” will be used in the cushioning materials (bubble wraps) for automotive parts, gradually aiming for a higher incorporation rate.

“pool resin” will be used in the cushioning materials (bubble wraps) for automotive parts, gradually aiming for a higher incorporation rate.

Future Prospects

From now on, Recotech plans to further automate data collection throughout the supply chain and improve credibility of their traceability with blockchain technology, enabling it to comply with third-party traceability certification requirements such as ISCC Plus for the entire information management process.

Furthermore, to ensure stable supply, Recotech will expand and secure their source of discharged plastics for pool resin, and strengthen collaboration with recycling partners to ensure stable supply of PCR materials.

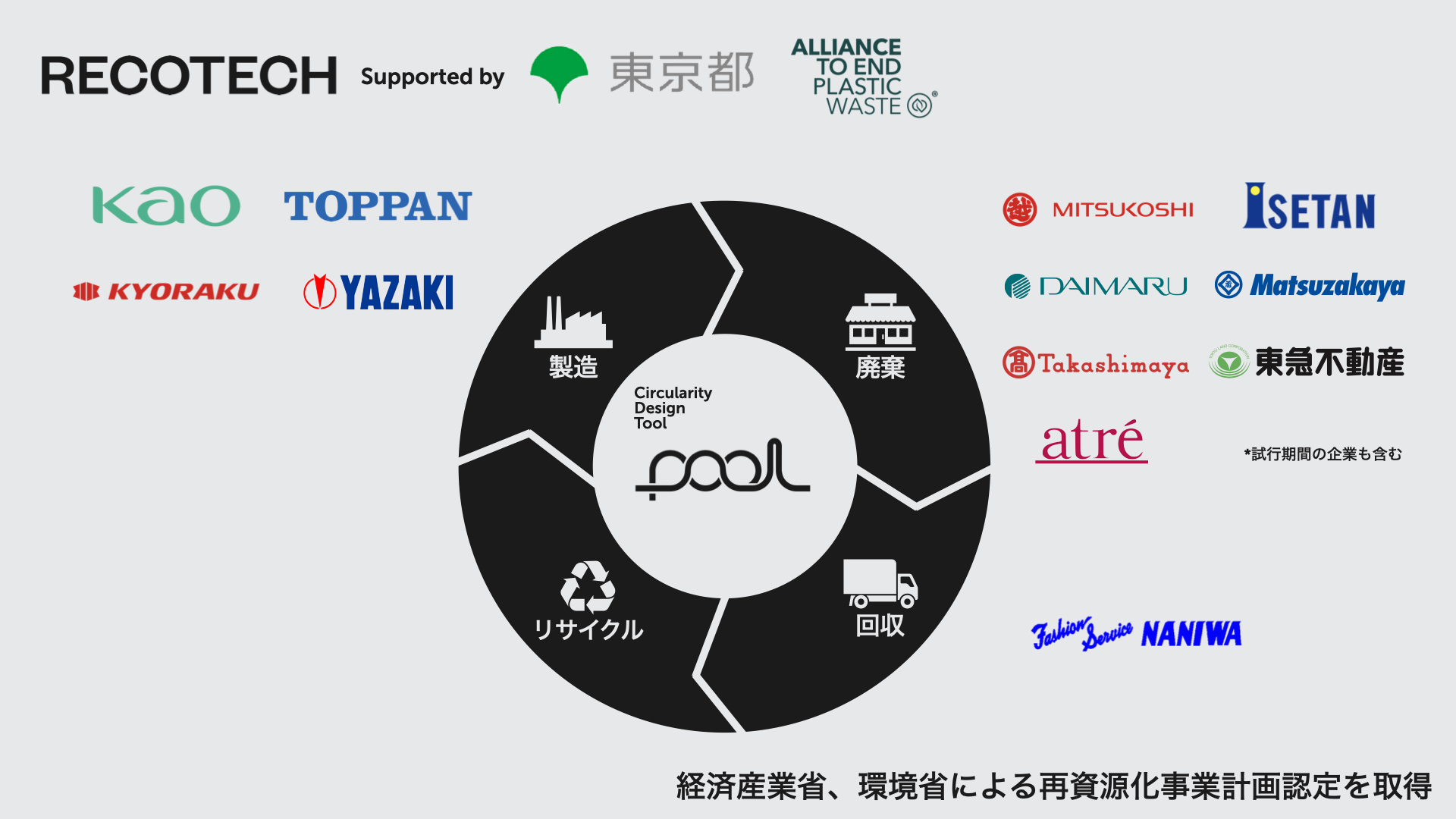

About Circularity Design Tool – pool

“pool” is a cloud service that transforms the end of resource value into a beginning. By digitizing urban resources, “pool” enhances collection efficiency, connects manufacturing companies that want to incorporate recycled materials into their products with dischargers, and enables us to design a circular supply chain. From waste to material, “pool” can prove and provide information on traceability and CO2 impact (scope3, category1&5) on every process throughout the supply chain, with each stakeholder simply inputting data with their smartphone or tablet.

About RECOTECH

Recotech is a Climate Tech Startup with a mission to “take responsibility for today’s problems, and build a sustainable legacy.” The current waste management system primarily involves incineration or landfill, leaving a burden for the next generation. Recotech aims to transform this structure through technology and to build a nature-positive economy.